How Period Panties are Crafted in Factories?

Dec 07,2024

Dec 07,2024

lynmiss

lynmiss

Introduction to period panties.

In the ever-evolving landscape of menstrual care, period panties have emerged as a game-changer, offering a sustainable, comfortable, and convenient solution for individuals during their monthly cycles. These innovative garments, designed to absorb menstrual flow, have revolutionized the way we approach period management, providing an eco-friendly alternative to traditional feminine hygiene products.

As society becomes increasingly conscious of the environmental impact of disposable menstrual products, the demand for reusable and sustainable options has skyrocketed. Period panties not only reduce waste but also offer a discreet and leak-proof solution, allowing individuals to go about their daily activities with confidence and ease. This growing demand has given rise to specialized manufacturing facilities dedicated to crafting these innovative garments.

The process of manufacturing period panties

The manufacturing process of period panties is a testament to the fusion of technology, innovation, and attention to detail. Let's delve into the intricate steps involved in bringing these game-changing garments to life.

Raw materials used in period panty production

The foundation of any high-quality period panty lies in the careful selection of raw materials. Manufacturers often opt for moisture-wicking fabrics, such as bamboo, cotton, or specialized synthetic blends, to ensure breathability and comfort. Additionally, specialized absorbent materials, like microfiber or polyurethane laminates, are incorporated to provide leak-proof protection.

Cutting and sewing the fabric

Once the raw materials are procured, the manufacturing process begins with precise cutting of the fabric components. Computer-aided design (CAD) systems and automated cutting machines ensure accurate and consistent patterns, minimizing waste and maximizing efficiency.

The cut fabric pieces are then meticulously sewn together, often by skilled seamstresses or advanced sewing machines. Attention to detail is paramount, as the seams and stitching play a crucial role in the garment's durability and leak-prevention capabilities.

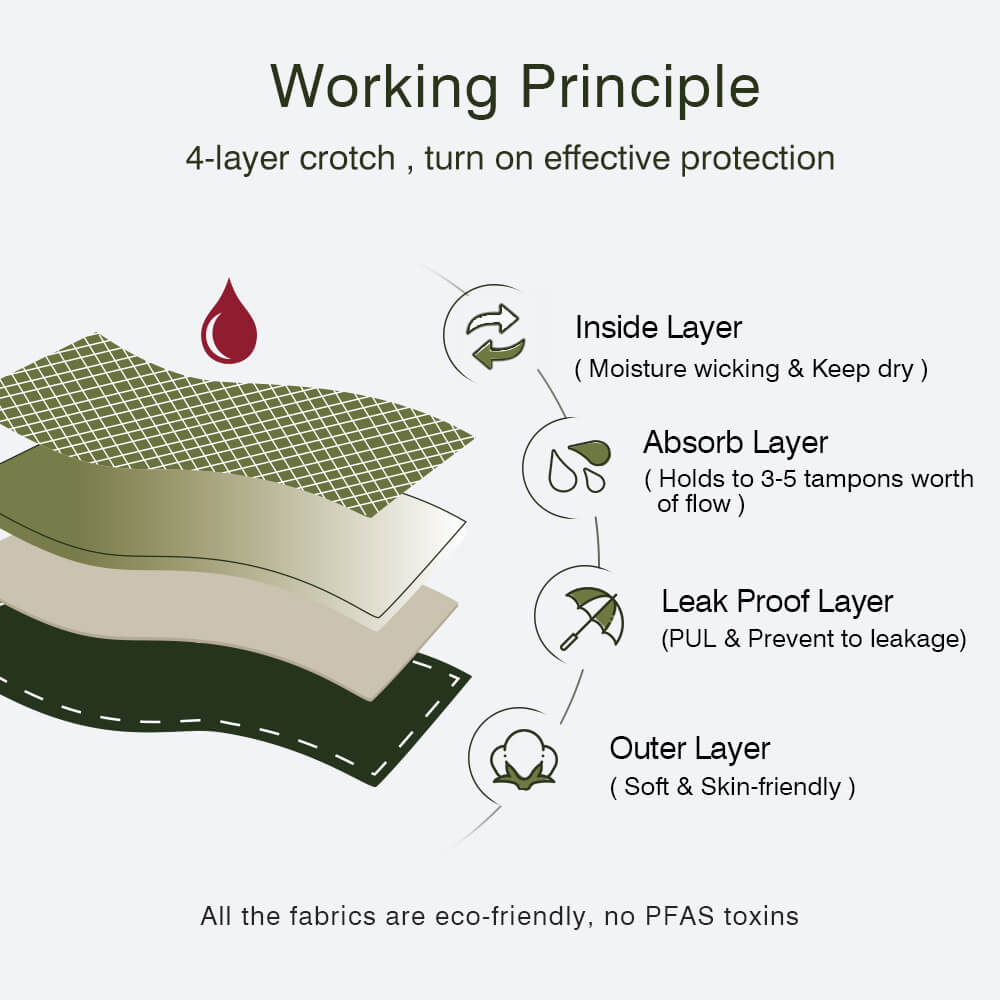

Adding absorbent layers and leak-proof barriers

At the heart of a period panty lies its absorbent core, designed to capture and contain menstrual flow. Manufacturers employ various techniques to incorporate these layers, such as laminating absorbent materials or strategically positioning leak-proof barriers within the garment's construction.

Some manufacturers opt for removable absorbent inserts, allowing for easy cleaning and replacement, while others integrate the absorbent layer directly into the panty's lining. The choice of method often depends on the brand's design philosophy and the desired level of protection.

Quality control and testing

Before a period panty can make its way to consumers, it undergoes rigorous quality control and testing procedures. Manufacturers conduct a series of tests to assess the garment's absorbency, leak resistance, and overall performance under various conditions.

These tests may include simulated wear trials, moisture management evaluations, and even specialized equipment that mimics menstrual flow. Only those period panties that meet stringent quality standards are approved for production and distribution.

Packaging and branding

Once the manufacturing process is complete, the period panties are carefully packaged to maintain their integrity and freshness. Brands often employ eco-friendly packaging materials, aligning with the sustainable ethos of their products.

Branding plays a crucial role in the success of period panties, as it helps establish a connection with consumers and communicates the brand's values and commitments. Manufacturers may incorporate branding elements such as logos, color schemes, and messaging on the packaging or even on the garments themselves.

LYNMISS Period panty factory standards and certifications

To ensure the highest levels of quality and safety, period panty manufacturers often adhere to industry-specific standards and certifications. These may include certifications for materials used, manufacturing processes, and even environmental sustainability practices.

Some of the common certifications sought by period panty manufacturers include:

- OEKO-TEX® Standard 100: This certification ensures that the materials used in the garments are free from harmful substances and meet strict safety and environmental requirements.

- GOTS (Global Organic Textile Standard): For manufacturers using organic cotton or other organic materials, this certification verifies the product's organic integrity throughout the supply chain.

- ISO 9001: This international standard focuses on quality management systems, ensuring consistent and reliable manufacturing processes.

- ISO 14001: This standard addresses environmental management systems, promoting sustainable practices and minimizing environmental impact.

By adhering to these standards and certifications, period panty manufacturers demonstrate their commitment to producing safe, high-quality, and environmentally responsible products.

Choose Lynmiss for reliable, comfortable, and eco-friendly period panties. Let us be your partner in menstrual care.